DEMYSTIFYING DEICING: WINTER PRIVATE JET TRAVEL & OPERATIONAL EXCELLENCE AT FLEXJET

January 24, 2025

By now, you have probably felt the wintery embrace of the new year in most corners of the United States. Regardless of the season or reason, the aviation industry must always prepare for the challenges that accompany snowy or icy conditions. For private aviation providers like Flexjet, the issue of deicing is not just a seasonal concern; it is a critical aspect of operational safety and efficiency. Here, we explore the importance of deicing, its purpose and process as well as its integral role in the broader maintenance or operational lifecycle.

WHAT IS DEICING?

Deicing refers to the processes used to remove snow, ice or frost from an aircraft before takeoff. This procedure is vital for ensuring that aircraft can operate safely and efficiently. In private aviation, where time is of the essence, effective deicing processes can save precious minutes and prevent delays that could impact a client’s travel plans.

The deicing procedure typically involves the application of specialized fluids designed to lower the freezing point of water and to remove ice that may have accumulated on the wings, tail, jet and even propellers of the aircraft.

There are two main types of deicing fluids: Type I, which is heated and used for deicing and Type IV, which is designed to provide anti-icing protection after the deicing process. Understanding the proper application of these fluids is crucial for private aviation operators.

KEEPING YOU SAFE IN THE SKIES

Safety is paramount in aviation (obviously) and deicing is a vital part of ensuring the aircraft’s airworthiness during winter months. Ice accumulation can significantly affect the performance of an aircraft. It alters the aerodynamic properties and can lead to increased drag, reduced lift and compromised control surfaces. These factors heighten the risk of incidents during takeoff and in-flight.

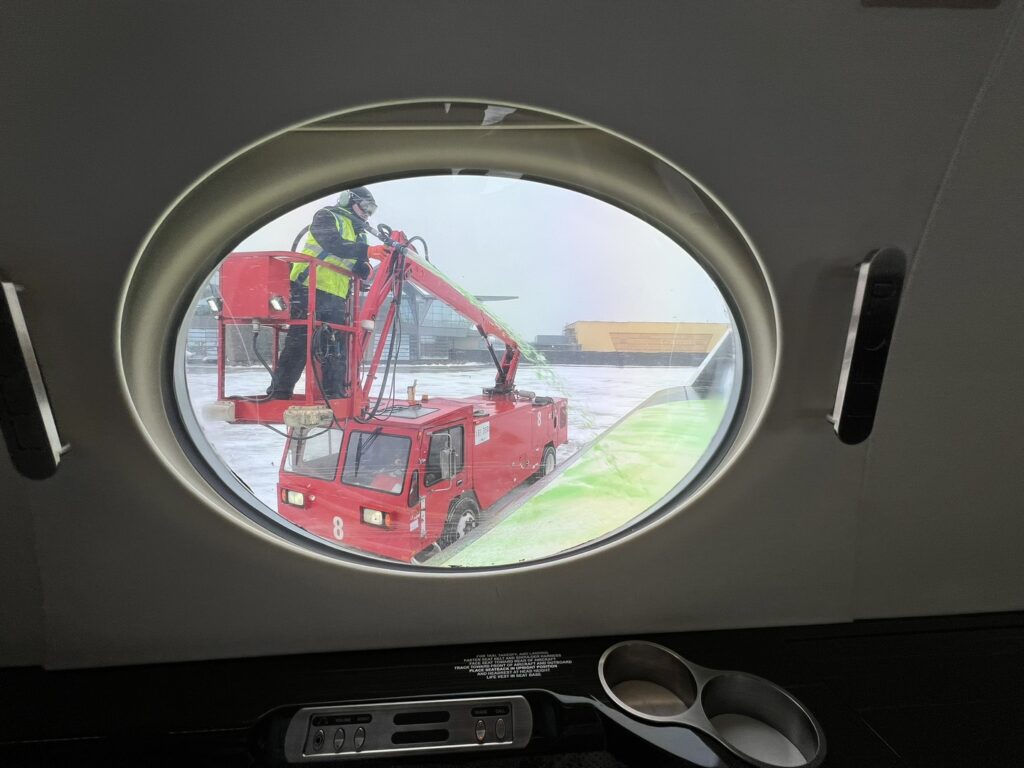

Flexjet employs rigorous deicing protocols to mitigate these risks. First, the condition of an aircraft is assessed by the pilot. If during this pre-flight walk-around, your pilot notices any presence of ice, snow or if operations anticipate incoming weather fronts with lots of moisture (in concert with cold temperatures), this protocol will be activated. The deicing process is generally two-fold. First an orange, heated liquid is sprayed on the entirety of the aircraft; this melts any existing snow or ice on the surface. If the forecast does not call for additional wintery weather, there is no additional action necessary and the aircraft will be cleared to depart.

If simply deicing the aircraft is not enough due to ongoing or anticipated weather patterns and the aircraft must operate through adverse conditions, a neon green anti-icing substance will be sprayed over its entirety. This is a Type IV substance that prevents ice from forming – however, depending on FAA-approved ‘holdover’ windows, the aircraft may need to immediately takeoff before the substance is washed away and the application must be repeated.

By ensuring every aircraft is thoroughly deiced before departure, the company safeguards its passengers, crew and aircraft from potential hazards associated with icy conditions. This commitment to safety extends beyond a single flight; it fosters a culture of diligence that permeates the entire operation.

ENHANCING OPERATIONAL EFFICIENCY

In the world of private aviation, time is a precious commodity. Clients expect timely departures and seamless travel experiences. Effective deicing procedures are crucial for minimizing turnaround times at airports. Flexjet has invested in state-of-the-art equipment and training for its ground crew to expedite the deicing process without compromising safety standards.

Moreover, efficient deicing minimizes the potential for flight delays and cancellations caused by winter weather. By maintaining a proactive approach toward winter operations, Flexjet ensures our aircraft Owners can trust their scheduled travel plans, even amid challenging weather conditions.

THE ROLE OF DEICING IN FLEXJET’S MAINTENANCE LIFECYCLES

Deicing plays a significant role in the overall maintenance lifecycle of aircraft, particularly in colder regions where ice and snow are prevalent. The accumulation of ice can lead to various mechanical issues if not properly managed. For instance, frozen components may strain systems beyond their intended capacity, leading to premature wear and potential failures.

Flexjet implements comprehensive maintenance protocols that include regular inspections and deicing practices.

By integrating deicing into the maintenance lifecycle, the company can proactively manage the wear and tear associated with winter operations. This approach not only extends the life of the aircraft but also optimizes performance and reliability.

KEEPING TABS ON YOUR TRAVEL

Flexjet’s maintenance and operations professionals in the new, cutting-edge Global Operations Control Center constantly monitor all flights in real-time, seeking out the most efficient routing and aircraft utilization possible. Weather delays are always possible, but we strive to communicate and coordinate before your flight to mitigate any major disruptions to your day.

Contact our team via our website to discover more about our fractional, lease or jet card programs and our exclusive travel services.

CLOSE